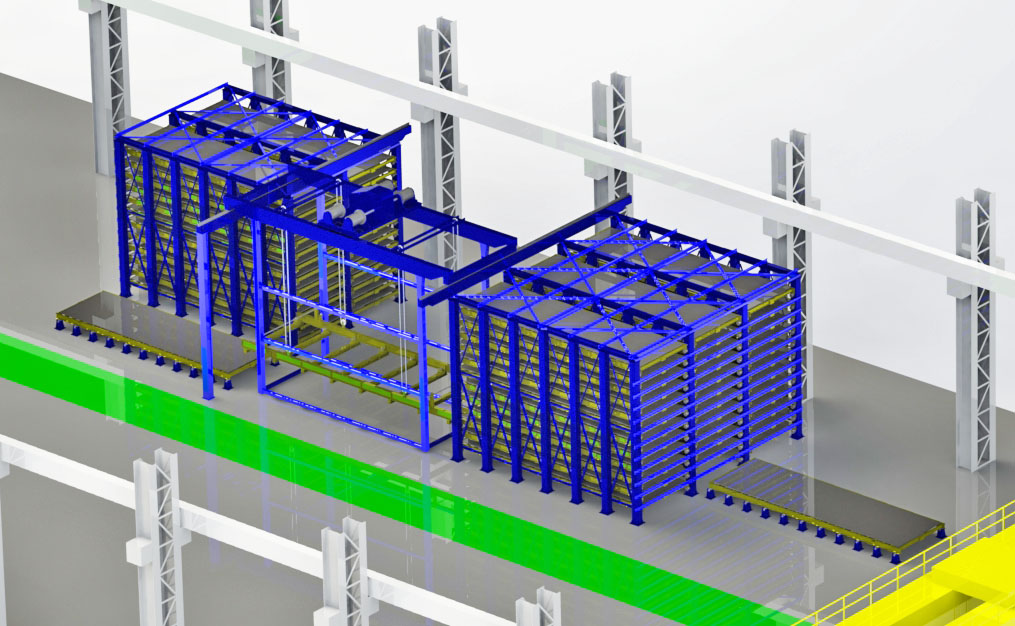

Stereoscopic Warehouse for Plate

The parts stored in tray-type stereoscopic warehouse include deck board, enclosure bulkhead board, T-profile web, toggle plate, patch plate, etc. All the parts are stored in trays and stored in stereoscopic warehouse. After sorting and distribution, trays should be transported to the entrance delivery system of the stereoscopic warehouse by crane equipped with container spreader. The entering delivery system and stacker crane will transport the trays to the assigned storage bins on the storage racks according to WMS instruction. When the trays are delivered out from storage, WMS will control the stock removal delivery system and stacker crane to take out the targeted trays according to outgoing list, and the trays will be sent to targeted stations by AGV of workshop.

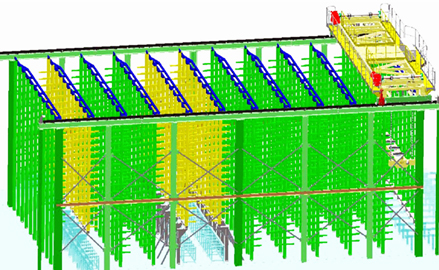

Profile Steel Stereoscopic Warehouse

Classified storage and caching of profile steel raw materials or finished products help users get rid of material deformation problem caused by traditional stacking and can improve the utilization rate of the workshop in the meantime. Through the WMS system independently developed by DIG, production task deployment and profile storage can be easily realized and connected with MES system and ERP system to improve task traceability and achieve comprehensive quality control.

Storage capacity: designed according to the actual situation of workshop, 300 units are generally recommended.

Take-in/send-out speed: a feed cycle can be completed in 150s on average (1 in, 1 out)